Industry 4.0 and ERP systems have become increasingly significant because their integration can bring several positive changes to an organization in the digital era.

They provide real-time data integration and analysis, which enables organizations to respond rapidly to changes in the market, customer demand, and supply chain.

According to Fortune Business Insights, the global Industry 4.0 is expected to grow by around $377.30 billion by the year 2029.

This implies that there will be increased demand for advanced technologies across different industries.

What is Industry 4.0?

Industry 4.0, also called the fourth industrial revolution, has revolutionized how organizations manufacture, improve, and distribute different products and services.

They have integrated multiple advanced technologies, such as cloud computing and analysis, Internet of Things (IoT), and AI and machine learning into production processes and subsequent operations.

Such organizations call themselves smart factories equipped with robotics, embedded software, and advanced sensors to collect and analyze data for enhanced decision making.

Korcomptenz has been a reliable Microsoft Dynamics ERP partner dealing with implementation and integration solutions to help clients leverage the benefits of Industry 4.0.

How Can Businesses Benefit from Industry 4.0?

Industry 4.0 is a technological shift that is transforming the way businesses operate and interact with their customers. There are several ways that businesses or brands can benefit from it.

1. Improved Efficiency

Industry 4.0 technologies such as the Internet of Things (IoT), artificial intelligence (AI), and automation can help businesses optimize their operations and reduce costs by streamlining processes and eliminating waste.

2. Enhanced Customer Experience

Businesses can gain valuable insights into all customer preferences and behavior instantly.

The process allows them to tailor their products and services to better meet their needs by using Industry 4.0 technologies such as big data and machine learning.

3. Increased Flexibility

Industry 4.0 technologies such as robotics and advanced analytics can help businesses adapt to changing market conditions and customer demands.

It allows them to stay competitive in a rapidly evolving business environment.

4. Improved Quality Control

Industry 4.0 technologies such as sensors and data analytics can help businesses monitor and control the quality of their products and services. The process ensures that they meet or exceed customer expectations.

5. Better Decision-Making

Industry 4.0 technologies such as AI and predictive analytics can help businesses make better-informed decisions by providing them with real-time data and insights into their operations and market trends.

Is Your Brand’s ERP System Ready for the Digital Era?

Industry 4.0 is the fourth industrial revolution driving the digital transformation of manufacturing and other industries.

As businesses adopt technologies associated with it, such as the Internet of Things (IoT), big data analytics, and automation, they generate unprecedented amounts of data that need to be processed and analyzed in real-time.

This is where they need the help of Enterprise Resource Planning (ERP) systems.

ERP systems integrate and automate business processes such as finance, supply chain management, and customer relationship management.

They manage internal operations and improve business efficiency.

However, with the rise of Industry 4.0, ERP systems need to be re-evaluated to determine if they are ready to take advantage of the new digital era.

One significant challenge is that traditional ERP systems may not be equipped to handle the vast amounts of data generated by Industry 4.0 technologies.

Moreover, new Industry 4.0 technologies such as blockchain and artificial intelligence (AI) require new capabilities that may not be available in traditional ERP systems.

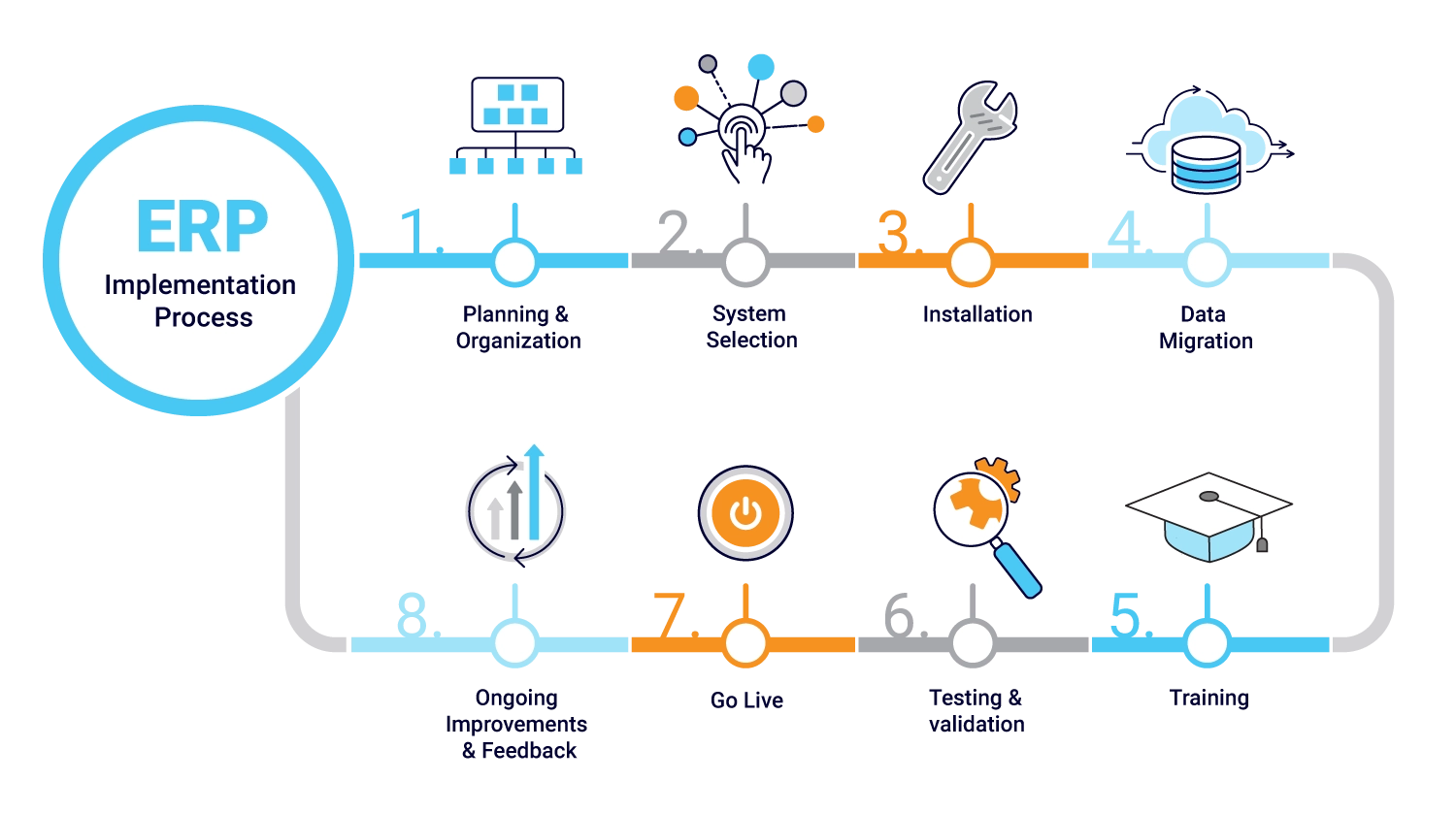

Businesses must take several steps to ensure ERP systems are ready for the digital era.

- Evaluate the existing ERP system to determine its readiness for the latest technologies.

- Identify the Industry 4.0 technologies most relevant to the business and assess their data processing and analytics requirements.

- Consider upgrading the ERP system to a more modern and flexible platform that can handle the data requirements of Industry 4.0.

- Integrate the ERP system with other Industry 4.0 technologies such as IoT sensors and AI to create a comprehensive digital ecosystem.

- Train employees on the new technologies and processes to ensure that they can effectively leverage the benefits of Industry 4.0.

Korcomptenz:

Your Go-to Partner for Industry 4.0-Powered ERP Systems

With the ever-evolving manufacturing landscape, it is crucial for manufacturing companies to adapt and refine their operations to remain competitive.

Korcomptenz is a reliable and committed technology transformation partner that has helped many manufacturing businesses achieve a 360-degree digital transformation with Microsoft Business Applications.

Korcomptenz provides support stabilization and maintenance for clients who are using legacy systems like Microsoft Dynamics AX 2009 and facing various challenges with their existing IT vendor.

Our team has extensive experience in integrating technologies such as Microsoft Dynamics AX 2009 with Salesforce via Biztalk and connect it with.

Woo Commerce to enable online self-service sales and improve user convenience, resulting in improved data flow that adds to your bottom line.

Our team also helps clients upgrade to Microsoft D365 Finance and Operations and achieve Industry 4.0.

Korcomptenz can be your strategic technology partner to future-proof your operations and customer engagement, ensuring efficiency, productivity, and profitability.